NEWS, EVENTS & BLOG

BLOG

The Best SBCs for Industrial Automation

Press Office, VersaLogic Corporation, 05/20/21

Industrial automation is implemented inside a factory where goods are manufactured and also outdoors in exposed process plants such as those associated with the chemical, oil, and gas industries. As a result, developers of industrial automation equipment are faced with a number of different challenges:

- Temperature extremes: The concern indoors is mainly around high temperatures. For outdoor systems, extremely cold temperatures are also a consideration.

- Mechanical stresses: Machinery can subject associated automation systems to high levels of shock and vibration

- Durability: Human operators typically work an 8-hour shift. However, automation systems are required to operate 24/7 with high reliability and maximized mean time between failures (MTBF).

- Security: Protecting against a cyber-attack is a key consideration due to the increasing connectedness of industrial automation systems. This is further accelerated by the drive to Industry 4.0 and the associated integration of information technology (IT) and operational technology (OT) networks.

- Minimization of Development Cost and Time: In common with other industries, speeding time to market and saving development cost is of great importance.

Many industrial automation systems are not in temperature-controlled environments

Many industrial automation systems are not in temperature-controlled environments

When looking for the best single board computer (SBC) for industrial automation applications, it’s not enough just to select one that meets performance and functional requirements. It’s critical to select one from a supplier that has experience of working with industrial applications and can help meet the challenges listed above.

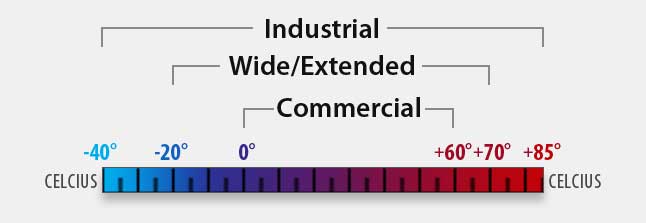

Withstanding Temperature Extremes

SBCs come in all shapes, sizes, and performance levels; they also are available in a variety of operating temperature ranges. In general, three ranges are commonly used:

- Commercial: 0° to +60°C (+32° to 140°F)

- Wide/Extended: -20° to +70°C (-4° to 158°F)

- Industrial: -40° to +85°C (-40° to 185°F)

As its name suggests industrial computers that operate over the full industrial temperature range are best suited for industrial automation applications for both inside and outside plant applications. A previous blog provides more information on this topic.

Build Tough to Combat Mechanical Stress

The SBC used in an industrial automation system may have to operate under high levels of shock and vibration. For that reason, it’s important to look for manufacturers that not only design but also test their industrial computers under high levels of shock and vibration.

Models and simulations are great tools, but there’s no substitution for powering up a product and hitting it with a 20g shock, or a range of vibrational frequencies. If there’s a weak spot, extensive physical testing to MIL-STD-202 will find it during development so that you don’t have to deal with it in the field. VersaLogic’s OEM Guide to Rugged Industrial Computers provides more details on this aspect of SBC design.

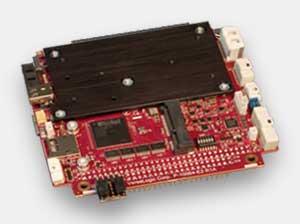

The compact Raven which features ADC inputs for analog sensors is used in equipment that monitors deep drilling systems

The compact Raven which features ADC inputs for analog sensors is used in equipment that monitors deep drilling systems

All Day and All Night

Having high uptime can require SBCs that can operate all day and all night, seven days a week. This is where it is important to select SBCs from suppliers that employ rigorous quality systems and have a track record of designing in reliability to ensure a lengthy MTBF from the beginning.

Having high uptime can require SBCs that can operate all day and all night, seven days a week. This is where it is important to select SBCs from suppliers that employ rigorous quality systems and have a track record of designing in reliability to ensure a lengthy MTBF from the beginning.

ISO9001 is familiar to many people. However, some suppliers, such as VersaLogic, go beyond and have been certified to AS9100. AS9100’s risk-tolerance is more stringent than the requirements within ISO 9001 with much more focus on prevention rather than corrective action.

The compact Owl, equipped with an Intel® “Apollo Lake” processor, has an MTBF estimate of >660,000 hours.

The compact Owl, equipped with an Intel® “Apollo Lake” processor, has an MTBF estimate of >660,000 hours.

Security

The SBC used in a system is a major contributor to security through technological means. This is a lengthy topic. Rather than repeating the details here, three previously posted blogs provide insights into important contributions to security:

- Processor-based security measures

- The use of Trusted Platform Modules (TPM)

- Securing remotely connected systems

Minimizing Development Cost and Time

The lowest development cost and the shortest development time can be achieved by purchasing a commercial-off-the-shelf (COTS) industrial single board computer. In some cases, it might be necessary to tweak the COTS product to make it fit with a specific application. That makes it important to choose a supplier that has significant experience in adapting COTS products. VersaLogic calls this their Modified COTS (MCOTS) process.

The MCOTS process is beneficial when any kind of customization is needed, such as when application-specific I/O needs to be added to an existing product. It can also be beneficial when transitioning from a discontinued product from another supplier, to a newer SBC. MCOTS can simplify and shorten the transition by modifying it to more closely match the connectors and I/O functions on the previous SBC. The case study “Migrating an Obsolete PC/104 Embedded Computer to a Long-Term Solution” provides an example of that for a manufacturer of industrial gas analysis and emissions monitoring systems.

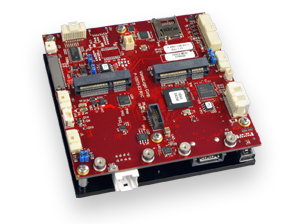

An MCOTS version of the PC/104-Plus BayCat was developed and engineering samples delivered within 90 days when a gas analyzer manufacturer’s previous supplier’s SBC was declared EOL

An MCOTS version of the PC/104-Plus BayCat was developed and engineering samples delivered within 90 days when a gas analyzer manufacturer’s previous supplier’s SBC was declared EOL

Choosing an SBC supplier that has processes in place to provide long lifecycle products is critical to avoiding/minimizing the costs and interruptions involved in having to perform mid-life redesigns when a short lifecycle SBC is declared EOL.

The Bottom Line

The best SBC for industrial automation is not just the one with the required features and performance. It must be supplied by a company with a history and understanding of the following:

- SBC operation over the full industrial temperature range of -40° to +85°C

- SBCs that withstand the shock and vibration rigors of MIL-STD-202

- Maximizing MTBF to meet demanding 24/7 operation by providing high quality products

- Addressing system security

- Minimizing development cost and timeline by having experience of supplying MCOTS products if necessary

- Minimizing ongoing lifecycle costs by having a demonstrated track record of long product lifecycles

Need additional Information?

Want to know more about VersaLogic’s range of embedded products? Let’s start a conversation.