VersaLogic Quality

Quality Processes Lead to Quality Products

What is product quality? Is it just one unit that is designed, validated, and manufactured to perfection? Five units? 100 units?

What is product quality? Is it just one unit that is designed, validated, and manufactured to perfection? Five units? 100 units?

Of course real quality is about manufacturing hundreds of thousands of units in a predictable way. How is that possible? It’s in the processes. It’s in the discipline to design and build products using only proven, time-tested procedures and checklists. These procedures make sure no assumptions are made, no shortcuts are taken, and no “improvements” occur unless they are fully vetted.

Can parts be substituted on the production line without testing, review, and authorization? Can a product design be changed without it being validated? Can changes be made without notifying all customers that use the product? VersaLogic’s highly-developed processes make sure that unintended changes of any type do not occur. The result? Extremely high-quality products and ever-increasing MTBF numbers.

Cut Your RMA and Field Repair Costs

Since most VersaLogic products are used in critical applications (such as medical, defense, and aerospace) product quality is essential. Ruggedness and reliability are the result of the highest design and manufacturing standards.

For decades, customers have relied on VersaLogic’s unwavering commitment to provide extremely high quality and highly reliable computer products. Quality processes are the key.

Cut your RMA and field-repair costs with a high-reliability VersaLogic embedded computer!

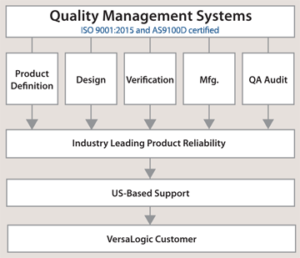

It Starts on Day One

VersaLogic has developed business values and quality controls that shape the processes from the earliest stages of design through manufacturing and technical support. Product quality and long-term availability start with product design, component selection, design validation, and hundreds of other steps that occur long before the product ever sees the manufacturing line. VersaLogic works from day one and step one to design quality and reliability into every product. The reward is products that serve customers beyond their expectations, and performance statistics that would make any manufacturer proud.

VersaLogic’s Quality Toolbox Includes:

- Long-term relationships with world-class suppliers

- Thorough qualification and verification processes for all components and materials

- Manufacturing to leading standards including: IPC-A-610, JEDEC STDs, ANSI/ESD-S20.20

- Stringent supplier selection criteria and ongoing performance management

- Quality audits of all production lots

- Locked BOMs and strict documentation controls

- Formal ECO processes

- In-house temperature testing

- In-house shock and vibration testing

- US-based design and validation

- Ethical sourcing

- Quality and security standards such as ISO 9001:2015, AS9100D, IPC-A-610, ISO 13485, ITAR

VersaLogic’s commitment to strict workmanship standards, automated and manual inspections, automated functional testing, and full-range extended temperature testing, yields extraordinary field reliability results. The commitment to rigid quality processes makes it possible for VersaLogic to offer one of the best warranties in the industry.

VersaLogic shows its commitment to quality through the relentless pursuit of zero defect performance. You’ll sleep a little easier knowing that you’ve got VersaLogic quality embedded in your system.