NEWS, EVENTS & BLOG

BLOG

The Best SBCs for Transportation Applications

Press Office, VersaLogic Corporation, 08/11/21

“Transportation systems” cover a wide range of applications. They include mobile (vehicles), fixed (infrastructure), or a combination of the two. Examples of transportation applications include:

- Monitoring of railroad rolling stock

- Active Traffic management systems

- Mobile digital media on taxicabs and other vehicles

- Autonomous vehicle control systems

- Steering control systems for large ships

Keeping track (pun intended) of railroad rolling stock is an important operational activity

Keeping track (pun intended) of railroad rolling stock is an important operational activity

With this wide variety of applications, there is no one type of embedded control system that is appropriate for them all. However, many have the same types of challenges. These include issues such as:

- Temperature extremes: For indoor systems, the primary concern is cooling. For outdoor systems, both cold and hot temperature extremes may be of concern.

- Mechanical stresses: This is usually associated with vehicular applications (with good reason). However, even in fixed infrastructure applications, high levels of shock and vibration may be a problem. One example would be the pole-mounted trackside readers associated with railroad wayside reporting systems.

- Durability: Transportation systems are required to operate 24/7 with high reliability and maximized mean time between failures (MTBF).

- Minimizing time and cost: In common with other industries, reducing time to market and saving development costs is of great importance.

There are additional applications related to transportation that pose challenges beyond those listed above. Here are links to two previous blog postings on aerospace and security applications.

Addressing these challenges is not trivial. Most of these don’t have any quick fixes. Working with an experienced supplier of embedded computers is essential to achieve the long-term performance that’s required in the field.

Withstanding Temperature Extremes

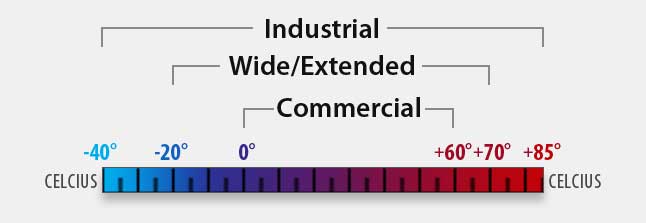

It is most likely that the best SBC for transportation applications will also be one that can operate over the full industrial temperature range of -40° to +85°C.

Manufacturers may also use other definitions of operational temperature range such as wide/extended or commercial. To be sure of the operating temperature range, it’s best to reference the specific temperature specs rather than a general description.

It’s also important to establish that the supplier has actually tested the SBC at temperature extremes. Thermal simulation is an important tool during the design phase; however, testing in an environmental chamber is a critical step to ensure that the SBC operates reliably over the stated temperature range. A previous blog post provides more information on this topic.

Build Tough to Combat Mechanical Stress

Vehicles and transportation infrastructure can subject systems to harsh mechanical stress. This means that SBCs used in such systems must withstand high levels of shock and vibration. VersaLogic’s SBCs are designed from the outset to meet MIL-STD-202 levels and then tested to verify that they do.

If there’s a weak spot, extensive physical testing during development will find it so that you don’t have to deal with it in the field. VersaLogic’s OEM Guide to Rugged Industrial Computers provides more details on this aspect of SBC design.

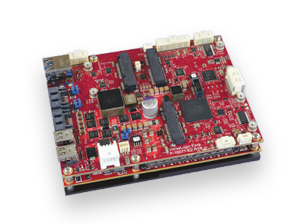

The Blackbird, designed for harsh environments, is used in a zero-emissions autonomous vehicle and features an Intel® Core™ processor for high performance embedded applications

The Blackbird, designed for harsh environments, is used in a zero-emissions autonomous vehicle and features an Intel® Core™ processor for high performance embedded applications

Continuous Operation Over a Long lifetime

Transportation systems must be able to operate 24/7 and infrastructure, in particular, must operate reliably over a long lifetime. This requires the systems and the SBC inside them to be reliable and to have a lengthy mean time between failures (MTBF).

Transportation systems must be able to operate 24/7 and infrastructure, in particular, must operate reliably over a long lifetime. This requires the systems and the SBC inside them to be reliable and to have a lengthy mean time between failures (MTBF).

This reinforces the need to select SBCs suppliers that employ rigorous quality systems and have a track record of designing in reliability to ensure a lengthy MTBF from the beginning.

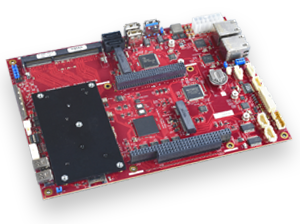

The Lion, used in an infrastructure application, has an MTBF of >2 million hours (228 years)

The Lion, used in an infrastructure application, has an MTBF of >2 million hours (228 years)

Minimizing Development Time and Cost

There’s no doubt that the lowest development cost and the shortest development time are achieved by designing around a commercial-off-the-shelf (COTS) industrial single board computer. This approach gives any project a 1+ year head start!

Even if the application has special requirements, COTS product can usually be tweaked to fit the needs of the application. It’s important to choose a supplier that has experience providing this kind of customizing to COTS products. VersaLogic calls this their Modified COTS (MCOTS) process.

The MCOTS process is beneficial when any kind of customization is needed, such as when application-specific I/O needs to be added to an existing product. It can also be beneficial when transitioning from a discontinued product from another supplier to a newer SBC. MCOTS can simplify and shorten the transition by modifying it to more closely match the connectors and I/O functions on the previous SBC. The case study “Migrating an Obsolete PC/104 Embedded Computer to a Long-Term Solution” provides an example.

The Viper is used in the demanding conditions associated with a naval vessel steering control system

The Viper is used in the demanding conditions associated with a naval vessel steering control system

The Bottom Line

The best SBC for transportation applications is not just the one with the required features and performance. It should be supplied by a company with a history and understanding of:

- Operation over the full industrial temperature range of -40° to +85 °C

- Withstanding the shock and vibration rigors of MIL-STD-202 or better

- Proven MTBF performance to meet long-term product deployment. Preferably with designed-in quality under a quality system such as AS9100

- Minimizing development cost and timeline by using COTS products, and having the option of ordering modified COTS products if necessary

Need Additional Information?

Want to know more about VersaLogic’s range of embedded products? Let’s start a conversation.