NEWS, EVENTS & BLOG

BLOG

OEM Guide to Rugged Industrial Computers

Press Office, VersaLogic Corporation, 03/17/21

The term “industrial” is used frequently in relation to single board computers (SBCs); but what does it mean? It’s implied that such SBCs can withstand the extreme stresses in many industrial environments. It is this strength to handle challenging environmental conditions that defines a rugged industrial computer.

It’s not just about some “shake, rattle, and roll” in industrial environments. It applies to other challenging sectors such as:

- Military/aerospace

- Energy – mining, oil & gas rigs, wind-farms

- Transportation – marine vessels, autonomous trucks, aircraft, and railroads

Mining presents severe conditions that require hardened solutions

Mining presents severe conditions that require hardened solutions

This blog will describe ruggedness and the design of rugged industrial computers. It will also touch on testing for ruggedness.

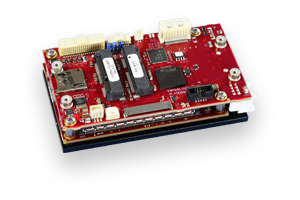

The Harrier – designed and tested for high vibration UAV environments

The Harrier – designed and tested for high vibration UAV environments

Elements of Rugged Industrial Computers

It’s easy to use the term rugged, but what does it mean? It’s mainly related to its ability to stand up to challenging environmental conditions.

The two conditions most often considered are mechanical stress and the ability to operate over a wide range of temperatures. This blog will focus on mechanical resilience. Operating temperature will be the subject of a future blog.

The Lion, ideal for use in rugged PC/104 board stacks in defense applications

The Lion, ideal for use in rugged PC/104 board stacks in defense applications

Design and Testing for a Mechanically Stressful Environment

To further narrow down the meaning of ruggedness, there needs to be some definition of the conditions. This requires reference to a standard. MIL-STD-202 (currently at revision H), is the standard most commonly referenced for industrial computer boards. This defines the levels of shock, random vibration, and sinusoidal vibration that a single board industrial computer must withstand.

Designing rugged industrial boards requires careful component selection and board layout. VersaLogic’s off-the-shelf boards have gone into space, been dropped below the earth’s crust, and faced numerous mechanical challenges. It’s the original design that allows reliable performance in hostile environments. There’s no substitute for designing with the right components, with the proper placement and the correct attachment to the PCB.

In addition, VersaLogic can provide additional measures for very high risk environments, such as:

- Stabilization of taller components

- Corner staking

- BGA underfill

The bottom line: VersaLogic is committed to providing rugged industrial computers that are highly resilient to shock and vibration.

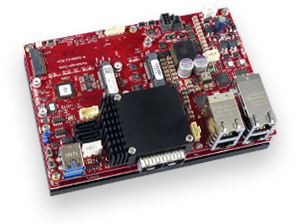

The Grizzly – a rugged micro server built and tested for resilience at the edge

The Grizzly – a rugged micro server built and tested for resilience at the edge

Designing industrial SBCs for high shock and vibration environments is the first step, but it does not prove their ruggedness. Models and simulations are great tools, but there’s no substitute for powering up a product and hitting it with a 20g shock, or 30 Hz vibration, or testing it against the full range of MIL-STD-202H requirements. That‘s what VersaLogic does to each and every board design before goes into production. Is there a weak spot? Extensive physical testing will find it during development so that you don’t have to deal with it in the field.

Need additional Information?

Want to know more about VersaLogic’s range of embedded products? Let’s start a conversation.